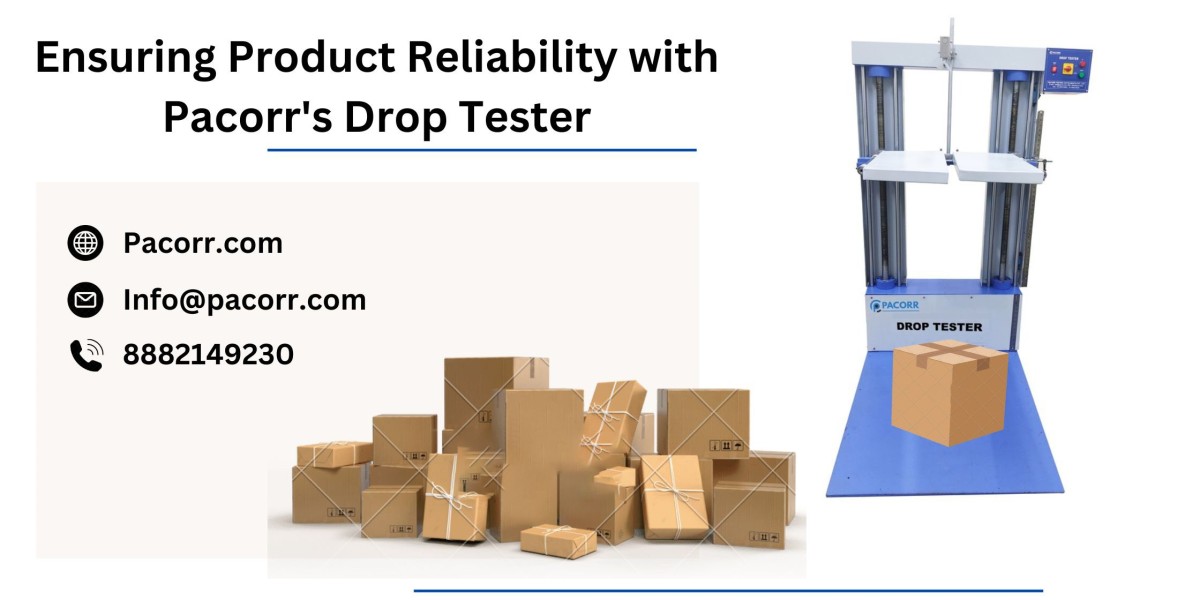

What is a Drop Tester?

A Drop Tester is a specialized device used to evaluate the impact resistance of products and packaging. By simulating drops from specific heights, it replicates the conditions a product might encounter during handling, transportation, and storage. This testing process helps identify potential weaknesses, ensuring the product's robustness and ability to withstand real-world challenges.

Key Features of Pacorr’s Drop Tester

Pacorr’s Drop Testing are engineered to deliver precision, reliability, and ease of use. Here are some of the standout features:

- Versatile Testing Capabilities: Suitable for a wide range of products, from small electronics to large industrial components.

- Adjustable Drop Heights: Allows for customization of drop heights to meet various testing standards and specific requirements.

- User-Friendly Interface: Equipped with intuitive controls and a digital display, making it easy for operators to set up and conduct tests efficiently.

- Robust Construction: Made with high-quality materials to ensure long-term durability and consistent performance.

- Comprehensive Reporting: Provides detailed test reports, enabling manufacturers to analyze results and make data-driven decisions.

Benefits of Using a Drop Tester

Incorporating a Drop Tester Price into your quality control process offers numerous benefits:

- Product Integrity Assurance: Regular drop testing ensures that products can withstand the rigors of real-world handling, reducing the risk of damage during transit.

- Enhanced Customer Satisfaction: Durable products lead to fewer returns and higher customer satisfaction, bolstering brand reputation.

- Compliance with Standards: Many industries have specific drop test standards. Using a Drop Tester helps ensure compliance with these regulations.

- Cost Savings: Identifying and addressing potential design flaws early can save significant costs associated with product recalls and repairs.

Applications of Drop Testers

Drop Testers are essential across various industries, including:

- Electronics: Ensuring gadgets and devices can endure drops and impacts.

- Packaging: Testing the durability of packaging materials and designs.

- Automotive: Assessing the resilience of parts and components that must withstand harsh conditions.

- Consumer Goods: Verifying that everyday items like appliances and furniture meet quality standards.

Choosing the Right Drop Tester

When selecting a Drop Impact Tester, consider the following factors:

- Product Specifications: Ensure the tester can handle the size and weight of your products.

- Testing Standards: Choose a tester that complies with relevant industry standards and testing protocols.

- Ease of Use: Look for features such as digital controls, adjustable drop heights, and clear displays.

- Durability: Opt for a tester constructed with high-quality materials to ensure long-lasting performance.

Conclusion

At Pacorr Testing Instruments Pvt Ltd, we are committed to providing high-quality testing solutions that help manufacturers uphold stringent quality standards. Our Drop Tester are designed to meet the diverse needs of various industries, ensuring your products are durable, reliable, and ready to face real-world challenges. Explore our range of Drop Testers and other quality testing instruments by visiting our website, pacorr.com.