Se trata de un género de contenedores de agua metálicos por los cuales el agua conserva íntegras sus características y no se contamina. El metal resguarda al agua de su interior de posibles bacterias y de los rayos ultravioleta. Depósitos de plástico para recoger agua de lluvia existen muchos en el mercado, pero la iniciativa de Leroy Merlin busca aunar estética y practicidad con un producto como el de la imagen. Diseñado en un color elegante como el antracita y con 80 litros de aptitud, está fabricado en un material duradero capaz de soportar las inclemencias de exterior. Su restauración para usos no potables en el hogar es de lo mucho más recomendable y su inversión no es tan elevada como logre parecer. A la inversa, ya existen artículos concretos y de empleo seguro para conseguirlo con eficacia.

Certificaciones de Calidad

El beneficio fundamental de los depósitos de agua cuadrangulares de agua es su sencillez para adaptarse al espacio donde se instalan (cuadrado, cuadrado, en forma de "L" etc). Dejan aun salvar columnas o dejarlas dentro de los propios tanques cuadrangulares. De esta manera, estos depósitos cuadrangulares alcanzan la máxima aptitud en el mínimo espacio debido a su ergonómica forma. La capacidad fluctúa entre 7 y 4.000 m3, dependiendo del diámetro (que varía entre 3 m y 30,5 m) y la altura (desde 1,25 m hasta 12 m).

Se trata de depósitos metálicos empernados y todos ellos se suministran con las conexiones y accesorios que requiera la instalación, con las medidas, calidades y según normativa solicitada por el cliente.

Aquamate giant metal water tanks, from 5,000 gallons to 102,000 gallons, can be found through our authorized dealers. All of our tanks are put in by Aquamate skilled and certified technicians, meaning you'll be able to be sure that your metal water tank will stand the test of time. Tank Connection is a number one international storage tank manufacturer for liquid and dry bulk storage applications. We are the one storage tank producer worldwide that designs, fabricates and installs all 4 major forms of metal storage tanks.

There’s an enormous spectrum of units obtainable so you’re sure to seek out the best one on the market. This machine will never burn or waste any espresso as the brew-pause function stops any drips if the carafe is removed. It’s easy to make use of as you just press a button and in 4-6 minutes, you get a full carafe of high quality espresso. Percolators and stovetop coffee makers won’t embrace any of these features. As they don’t have any electronics to automate any features of coffee-making.

Other species can be found but are only used if specified for a particular project. This wood can only be used for water tanks after the wood is chemically handled and kiln dried. For the ethanol-water separation represented in Figure 2.5, if the data had been collected from a column with seven levels, what is the total column efficiency? Tank Connection is the leader in fireplace protection storage tanks, shipped worldwide. Recognized for unmatched performance of RTP tank construction and Fusion coating system. Specifications for dry bulk storage metal tank including design standards; supplies; manufacturing unit utilized, epoxy powder-coat; bolted RTP (rolled, tapered panel) tank structure; area erection procedures; testing and warranty. CB&I is the world's main designer and builder of storage amenities, castelo d água metalico tanks and terminals.

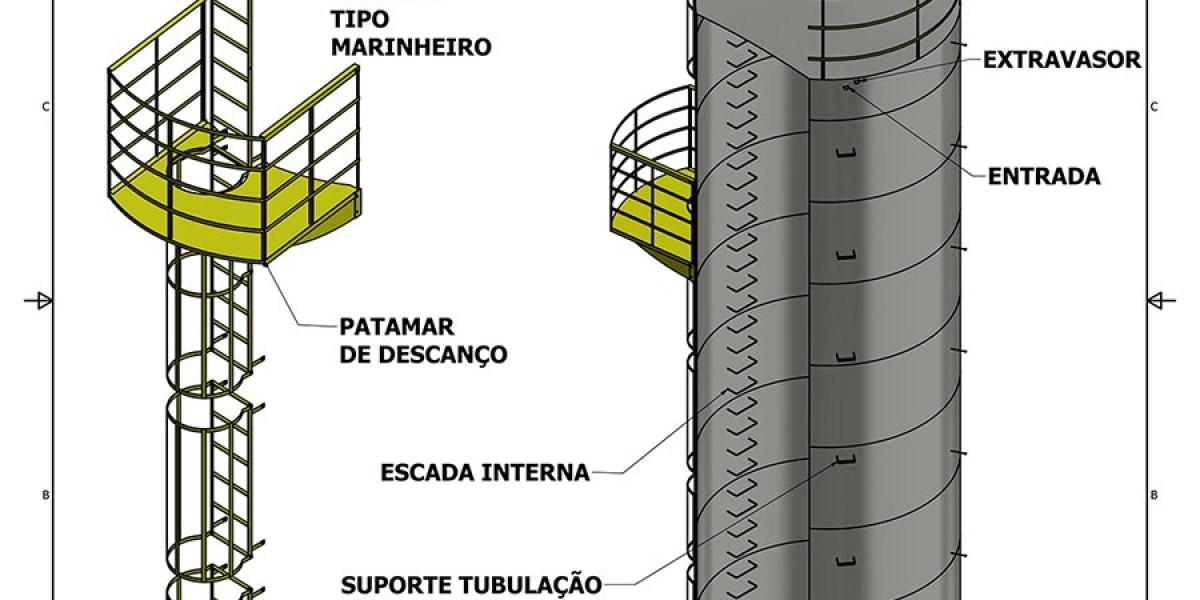

Other species can be found but are only used if specified for a particular project. This wood can only be used for water tanks after the wood is chemically handled and kiln dried. For the ethanol-water separation represented in Figure 2.5, if the data had been collected from a column with seven levels, what is the total column efficiency? Tank Connection is the leader in fireplace protection storage tanks, shipped worldwide. Recognized for unmatched performance of RTP tank construction and Fusion coating system. Specifications for dry bulk storage metal tank including design standards; supplies; manufacturing unit utilized, epoxy powder-coat; bolted RTP (rolled, tapered panel) tank structure; area erection procedures; testing and warranty. CB&I is the world's main designer and builder of storage amenities, castelo d água metalico tanks and terminals.Distillation Column Internals

With Caldwell, you can trust that your water storage needs shall be met with superior quality and craftsmanship. Some corporations could supply wood water storage tanks that may potentially have a brief life span as a outcome of the usage of wood grades that are not appropriate for water bearing buildings. Where $ f_2 $ is the fraction of the column cross-section space or internet area that is available for vapour move by way of the tray. The worth of $ f_2 $ is typically zero.85~0.ninety five, meaning that $ (1-f_2) $ is the fraction of the column area that's wanted for downcomers. The diameter calculation could be carried out using vapour move fee in the rectifying part, stripping part, Castelo D áGua Metalico or the typical, and considered one of these values will yield the utmost diameter. The largest calculated diameter would be satisfactory for the design of most separation systems (Wankat, 1988).

Setting the Standard for Effective Water Management

However, at high vapour velocity, small droplets of liquid may be carried up by vapour to the highest tray, causing sufficient entrainment and even flooding, and far decreased stage efficiency. As properly, excessive vapour flow price and deep liquid stage on the tray each end in excessive strain drop for the vapour to flow through the tray. The results of the operation situations, usually characterised by hydrodynamic terms such as froth top, flooding, and strain drop, are important features for distillation column design, operation efficiency, and column effectivity. When trying to increase column capacity past design charges, an operator might discover loss in separation efficiency or excessive stress drop, indicative of both vapor part or liquid part hydraulic limitations. Jet flooding, also referred to as entrainment flooding, is caused by large entrainment of liquid to the tray above. As the tray loading will increase, a two-phase combination of spray or froth begins to occupy increasingly more of the clear vapor area between the trays. At very high vapor charges, the mixture fills up the entire tray spacing, causing entrainment of great amounts of liquid to the tray above.

NSF/ANSI 61 Certified for Potable Water Use Tank Liner

Entrainment also recycles liquid upward, increasing tray weir loads, froth peak, and downcomer hundreds. All these factors lower the trays hydraulic capacity, ultimately leading to column flooding.Jet flood could be alleviated through a tray revamp by increasing active space, growing tray spacing, or switching to a excessive capability deck design. An improve in energetic area serves to lower the overall vapor velocity upwards by way of the column. In easiest terms, a 10% enhance in lively space should lead approximately to a 10% enhance in capability. An increase in tray spacing simply increases the gap that the vapor has to travel before it entrains liquid.